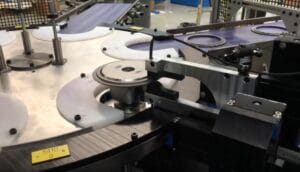

Transmission Clutch Eddy Current Inspection System

Eddy current component inspection system for the automotive & aerospace industries.

Best Solution for Inspecting Transmission Clutch Plates Pre-Production

The transmission clutch inspection system is a pre-production non-destructive testing process used by industries worldwide to inspect manufactured components before going into final production. Using a cnc eddy current system combined with a laser inspection, the eddy current testing system provides instant verification allowing manufacturers to detect flaws or defects in the metal as well as capture the complex internal geometry of parts without needing visual access or destroying the part.

- Laser Inspection

- Structural Evaluation

- Automatic Sorting

How eddy current technology works

Salem NDT systems provides continuous inspections for transmission components without loss of quality, stability or character

- Electromagnetic induction is used for testing alloys for flaws and defects

- Probes generate alternating current flows through a wire coil

- Oscillating magnetic fields are used in close proximity to a conductive material

- Eddy current (creates circular flow of electrons) flows through metal for 100% zero rate inspection

This pre-production inspection process is used by industries worldwide to inspect the components before going into final production. This method of inspecting parts provides instant inspection and verification allowing manufacturers to detect flaws or defects in the metal as well as capture the complex internal geometry of parts without needing visual access or destroying the part and providing the highest testing standards in the industry.

Manufacturers in the automotive and aerospace industries use lasers because they provide a nondestructive mechanical and structural evaluation that is both efficient and precise for parts, equipment, repairs, and products.

Salem NDT’s eddy current testing solutions allow you to store, retrieve and analyze data from eddy current inspection systems in a centralized location, across the entire enterprise, enabling you to put your machine testing images and data to work.

Get a Personalized Estimate For a Transmission Clutch Inspection System

With such broad capabilities, Salem Design and Manufacturing partners with corporations to custom design and build non-destructive testing machines that can sort, test and inspect parts to a degree not easily achieved with human or other optical inspection systems. Fill out the form below and we’ll get back to you to get more details.